Logística Friseco doubles its cold storage capacity while maintaining high standards of efficiency and sustainability.

Founded in 2015, Logística Friseco is a specialized logistics platform that offers advanced cold storage solutions tailored to the needs of companies operating in temperature-sensitive sectors. With a strong focus on reliability and operational excellence, the company offers a comprehensive suite of services including frozen and refrigerated storage, order picking, cross-docking, distribution and groupage. Its facilities are designed to withstand the growing demands of industries where cold chain maintenance is critical.

The challenge:

In 2024, Friseco Logistics experienced a significant increase in demand for cold storage capacity, driven by evolving consumer habits, stricter regulatory standards, and the expansion of the perishable goods market. To meet this challenge and future-proof its operations, the company launched a strategic investment plan totaling €4 million. This initiative aims to double its cooling storage capacity of 1,000 kW, enabling the company to serve a wider customer base and ensure operational agility.

The original refrigeration capacity of the logistics centre allowed the storage of approximately 3900 pallets with standard loads. The goal of this project is to achieve a doubling of capacity while reducing energy consumption and increasing efficiency.

Fundamentally, this expansion must be executed with a strong commitment to sustainability and energy efficiency. The company is integrating climate-tech refrigeration technologies to reduce energy consumption and carbon footprint, aligning with broader environmental goals and customer expectations.

With this investment, Logística Friseco not only strengthens its position in the market, but also establishes a benchmark for innovation and sustainability in the cold logistics sector.

The solution:

Logística Friseco chose Enex Technologies based on a set of strategic and technical criteria that aligned perfectly with its vision of sustainable growth. As a European multinational committed to decarbonization and the use of natural refrigerants, Enex Technologies offered the ideal combination of innovation, environmental responsibility and proven performance.

The decision to once again rely on the same partner followed the success of a similar installation in 2025 and was driven by the following key benefits:

• Use of R717 (ammonia), a natural refrigerant with zero ozone depletion potential (ODP) and zero global warming potential (GWP).

• High coefficient of performance (COP) in all temperature ranges, especially when using screw compressors.

• Fast return on investment compared to other natural refrigerants.

• A strong track record in delivering scalable, energy-efficient refrigeration systems tailored to industrial cold storage needs.

To bring this ambitious project to life, Enex Technologies delivered a fully designed refrigeration solution in collaboration with trusted installer Vladimir Zamora. Leveraging its deep expertise in natural refrigerant systems and industrial refrigeration, Enex Technologies designed a robust, high-efficiency system tailored to Friseco’s operational needs and sustainability goals. The facility integrates advanced components in compression, heat exchange, and control technologies, ensuring optimal performance, energy savings, and long-term reliability.

The solution includes:

Refrigeration Units

• Three MYCOM SCV200VM-M screw compressor units, designed for evaporation temperature of -28°C and condensation at +35°C.

• Total cooling capacity: 1,050 kW.

• Equipped with variable frequency drives for energy-efficient part-load operation.

• Open economizers (OPEN FLASH) to optimize the performance of low-temperature services.

Pump and pressure vessel group

ENEX TECHNOLOGIES also designed and manufactured:

• Complete group of NH3 pumps with HERMETIC pumps.

• Complete set of pressure vessels: liquid receiver, particle separator, valves, controls, level indicators and open economizer.

Heat exchangers

• Eight ventilated units: ECI104E6M80L HGVs, each with a capacity of 85 kW (T_evap = -28 °C, T_air in = -22 °C).

• Four additional units: ECI103C4L80H HGV, each with 52 kW.

• All with stainless steel tubes and fins, offering durability and corrosion resistance.

Condensing System

• Selected evaporative condenser: NCX-7V22D10H.

• It features electronically switched (EC) fans for optimal energy efficiency.

• Constructed with fiberglass-reinforced polyester housing for superior corrosion resistance.

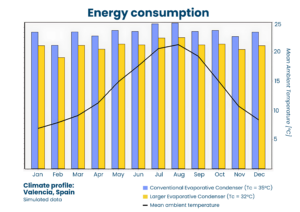

• It allows condensation at 32°C, saving up to 9% of energy compared to traditional systems.

Advanced Controls and Monitoring

The plant is managed using the latest control technologies:

• SIEMENS industrial PLC for robust process control.

• The integrated SCADA system allows for real-time remote monitoring and optimization of all plant processes.

• Floating condensation control and low condensing pressures further improve energy efficiency.

Results

The new facility positions Logística Friseco as a regional leader in sustainable cold storage logistics, delivering operational excellence and environmental responsibility. The main results of this installation include:

- The doubling of cooling capacity from 1,000 kW to 2,000 kW. This allows Friseco to more than double the number of pallets stored from 3900 to 8100, which allows Friseco to serve a greater number of customers while maintaining high standards of efficiency and sustainability.

- State-of-the-art control systems ensure precise temperature management and operational flexibility, enabling real-time monitoring, remote diagnostics, and adaptive performance optimization through an advanced SCADA platform.

- Environmentally friendly operation made possible by the exclusive use of natural refrigerants such as ammonia (R717), combined with low-emission components and corrosion-resistant materials, supporting Friseco’s long-term decarbonization strategy.

- Significant energy savings achieved through the integration of high-efficiency screw compressors, EC fan technology, and floating condensation control, resulting in lower operating costs and lower energy consumption. The annual energy savings with a selected larger capacitor is 9.4%:

Conclusion

This project is a clear demonstration of how Enex Technologies, through its Enex Industrial Division, offers fully integrated all-in-one solutions that combine engineering excellence with a strong commitment to sustainability. From initial concept to final commissioning, Enex Technologies designed all key components of the system ensuring seamless integration and optimal performance.

Leveraging decades of experience in industrial refrigeration, the company applied a holistic approach that balances CAPEX and OPEX, while maximizing energy efficiency and long-term reliability. This comprehensive methodology not only simplifies project execution for the client, but also ensures measurable value, environmental responsibility, and operational excellence at each facility.

Comments:

The Friseco Logistics Directorate: “Choose Enex Technologies and INDUSTRIAL REFRIG. ENGINEERING 2021 SL was a strategic decision aligned with our sustainability and efficiency goals. Their expertise in ammonia-based systems and their commitment to decarbonization matched our vision for cold logistics. With its engineering and Vladimir Zamora’s execution, we doubled our capacity and reduced our environmental impact, achieving energy savings, operational flexibility and a future-proof facility.”

INDUSTRIAL REFRIG. ENGINEERING 2021 SL: “This project shows how engineering and sustainability can work together. With Enex Technologies, we deliver a system that meets Friseco’s needs and reduces emissions. From ammonia cooling to EC fans and smart controls, every detail was designed for efficiency and environmental stewardship.”

The Commercial Management for the Industrial Applications segment of Enex Technologies: “We are proud to see that our all-in-one industrial refrigeration solutions allow Friseco to expand its operations while significantly reducing energy consumption and environmental impact, demonstrating how innovation can drive both business value and climate responsibility”