Transgourmet Polska has remodeled a hypermarket in Warsaw with all the refrigeration and AC /HP with natural refrigerant CO2

Transgourmet Polska, owner of the retail brands Selgros & Transgourmet is one of the European leading retail companies. It has commercial centers in Germany, Switzerland and also in western Europe countries, like Romania and Poland. Transgourmet Polska is at the very forefront regarding use of natural refrigerants in their shops, since many years.

They have decided to go further, extending the use, in their commercial centers, of natural refrigerants to space heating and cooling.

Frigo-Consulting, one of the leading European design & Project management companies, based near Bern, operating as a consultant/designer for Selgros, has a long experience in CO2 systems, and also in integral units, combining refrigeration with the production of heat and cold for climatization.

The problem:

Refrigeration is using more and more natural refrigerants, Carbon dioxide, Propane and Ammonia. Introduced again in commercial refrigeration in the first years 2000’s, after decades during which it was completely forgotten, CO2 systems are now a standard choice.

In commercial buildings there are also other users with synthetic refrigerants, like, for example, chillers for air conditioning and heat pumps for space heating. Due to electrification process, within the wide energy transition process, heat pumps are being used more and more.

In the supermarkets and hypermarkets however, it is not practical to use flammable or toxic refrigerants. For this reason, only CO2 is the ideal refrigerant.

Intrinsically a CO2 transcritical system is more complex of a “simple” refrigeration system with synthetic refrigerants. All that has blocked for years the extension of the use of CO2 to other applications. Moreover, the idea of combining the use of “warm side” and “cold side” of a refrigeration system is very attractive, because energy wise such system can be in overall very efficient. Two identical units were designed. For each one the following capacities were selected:

| KW | Conditions | |

| MT Load | 200 | -3°C evap temp |

| LT Load | 32 | -28°C evap temp |

| AC Load | 150 | 152 kW at +5°C (water 16-10°C) |

| Heating Load | 360 | Water 27 42°C |

| Sanitary Water | 100 | Water 25 72°C |

The solution:

Since several years Enex is producing “ELBA integral systems”. Beside refrigeration, ELBA produces hot water for winter heating and cold water in summer for cooling the space. Until now the interest was concentrated in some countries for small plants. After several installations during which the design was optimized and refined, it was the moment to spread out this solution also for hypermarkets.

A further specification was to maximize energy efficiency. All the most innovative design solutions developed by Enex were considered, including one solution particularly efficient, that is liquid ejector for semi-overfed evaporation.

It is worth to remind that “liquid ejector” overfeeding is an invention of Enex, which filed several patents about it and installed so far several hundreds of systems. The original Enex solution has no rivals in terms of efficiency, simplicity and reliability.

Comments:

Mr. Krzysztof Błauciak from Frigo-Consulting: “We are more than satisfied with truly efficient and energy-saving integrated installation with no oil return problems or anything else!”

Mr. Bartosz Jankowiak from Transgourmet Polska: “This CO2 installation with heat recovery, as well as other store functions, such as LED lighting, are part of our mission to reduce emissions harmful to the climate and protect valuable resources”.

Mrs Joanna Lenk from Epta Systemy Chłodnicze Sp.zo.o. (formerly Viessmann S.C.): “I am proud and happy that we managed to meet high-level and very specific requirements of such a project. Thanks to the technologically advanced ELBA CO2 units and high-quality refrigeration cabinets, we are able to achieve great evaporation level: -2°C on MT and -26°C on LT side, which together results in a very energy-efficient installation.”

Sergio Girotto, CTO Enex Technologies: “We followed Frigo-Consulting specifications, which point in the right direction: reinforcing the decarbonization process particularly during the hot season, when air conditioning plays an important role”.

In terms of environmental impact and energy saving the values for which the system are designed are very positive. Each of the two installed ELBA machines provides:

| Thermal energy kWh/year | Predicted system energy consumption kWh/year | Total system energy consumption (with new technologies) kWh/year | |

| Refrigeration load annual energy | 750.000 | 340.320 | 280.100 |

| AC energy | 110.000 | 63.200 | 58.200 |

| Heating energy | 150.000 | 80.400 | – |

| Total energy reference | – | 483.920 | 338.300 |

| -30% |

The plant allows in impressive saving in CO2 emissions, about 70 tons/year due to lower energy consumption and mostly a lower CO2 equivalent emissions when compared to a synthetic refrigerant due to leakage in the atmosphere: it is sufficient to say that using a natural refrigerant for such a plant size, with a charge of about 500 kg, the “content” in the circuit is reduced by 1000 equivalent tons of substances producing greenhouse effect.

Energy saving compared to standard solutions is due to several factors:

- Thermal recovery of free heat

- Recompression of flash vapor

- Recovery of expansion energy with ejectors

- Saving due to liquid ejector

- Innovative air conditioning system

- Use of modulating 3 way ball valves before the heat exchangers

Luis Crespo, President of the Commercial Refrigeration & HVAC businesses units of Enex technologies added: “Our mission is to support the global energy transition through Climate-Tech solutions while making our customers successful. We are committed to continue on our efforts to be pioneers in natural refrigerant technology for HVACR.”

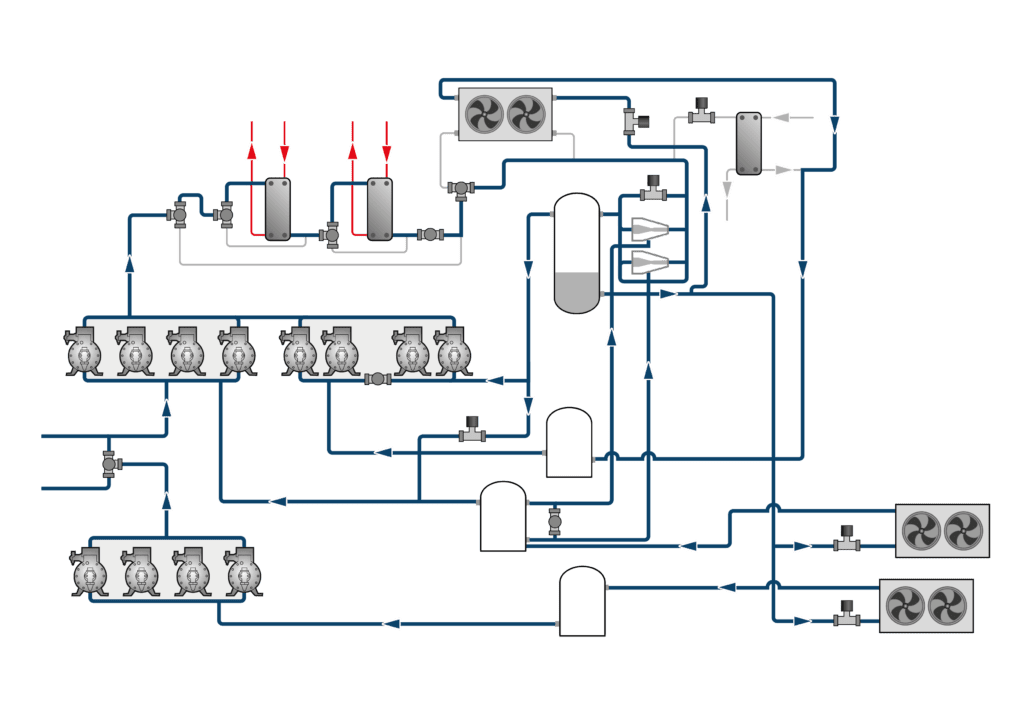

Operation Simplified Schemes

Scheme 1:

Commercial Refrigeration: Medium & Low Temperature

Heat pump operation.

Sanitary heating

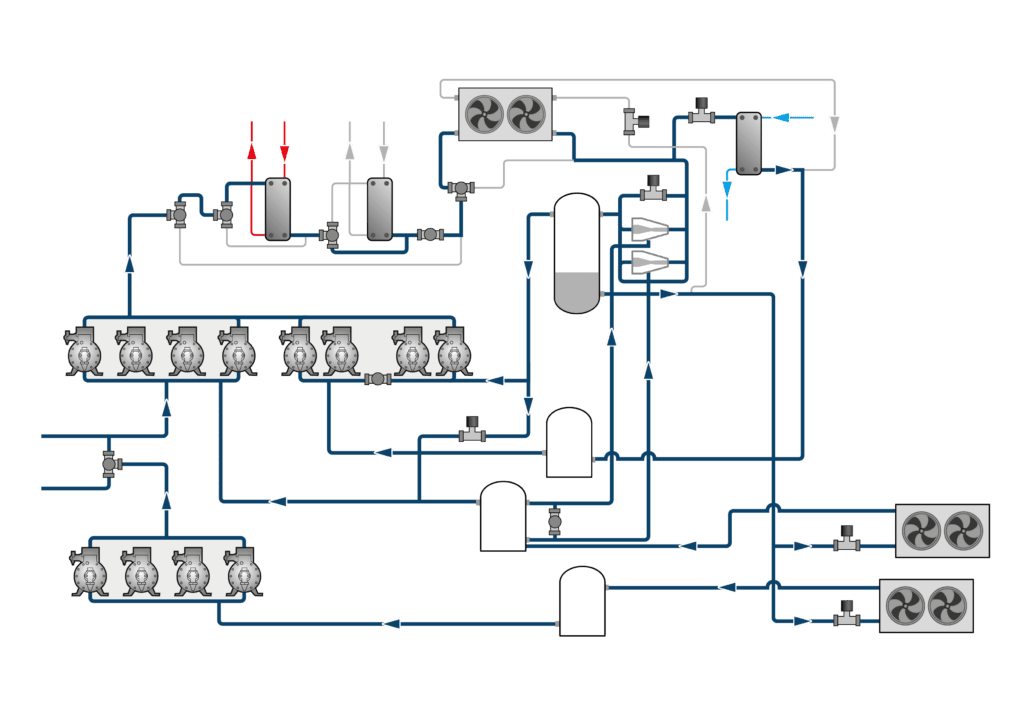

Scheme 2

Commercial Refrigeration: Medium & Low Temperature

Summer Air Conditioning Operation.

Sanitary heating recovery

Let us know if you want to know more about Enex Technology solutions to significantly decrease the emissions of your business.